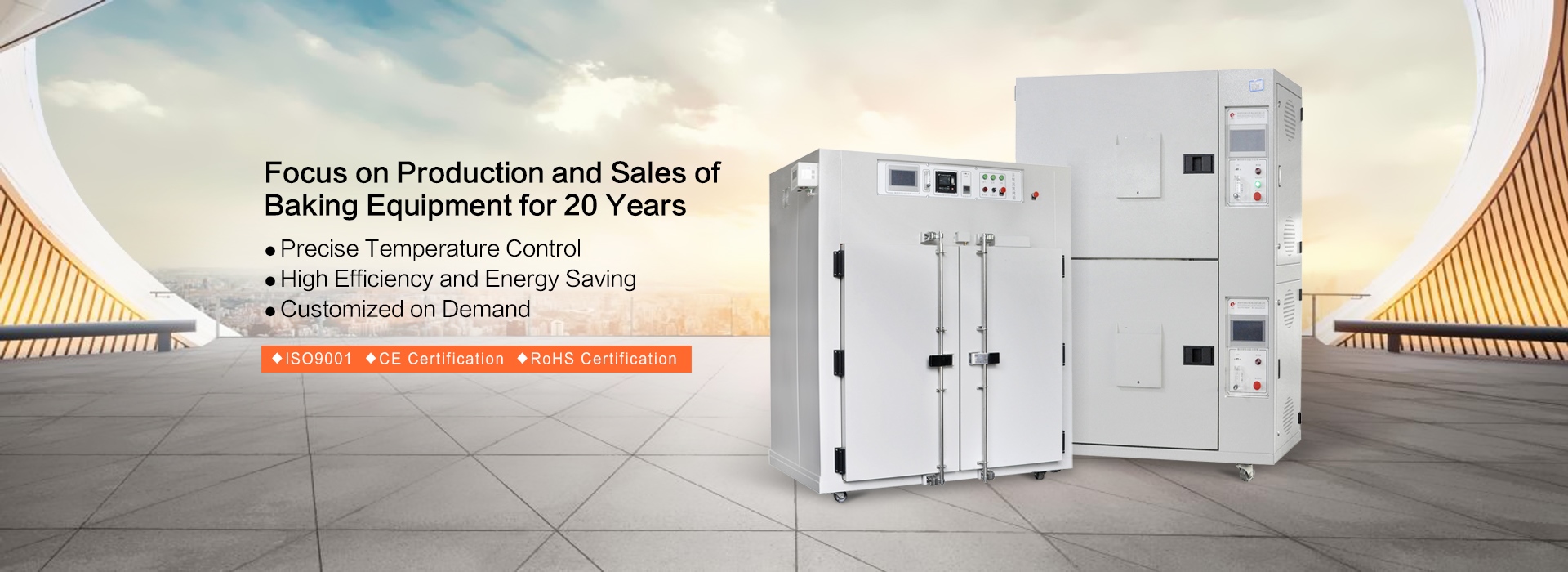

Tunnel curing furnace

Product description

Features

PRODUCT FEATURES

1. Composition and description:

The tunnel furnace is mainly composed of: conveying system, hot air drying system, automatic heating temperature control system, circulating air system, electrical control system; cooling and cooling system, etc.

The tunnel furnace adopts the relay automatic control form, except for manual loading and unloading of the workpiece, all other technological processes are automatically completed by it. Manually only need to place the workpiece to be dried in the leveling zone of the conveyor belt, and the conveyor system will automatically send the parts to each process section in sequence. After the workpiece is dried and cooled, it reaches the unloading station, and the drying process is completed. .

2. Conveying system

The tunnel furnace conveying system consists of a transmission, a conveyor belt, a main drive shaft, and a driven shaft. The conveyor belt can adopt various conveyor belts such as stainless steel mesh belt, Teflon, PVC, roller, chain plate, etc. according to the specific situation. (The material is determined according to the actual situation of the customer) The conveying speed can be continuously and steplessly adjustable within 0~6m/min.

3. Hot air drying, automatic temperature control heating system

The hot air drying and automatic temperature control heating system of the tunnel furnace is composed of a fan, a heating tube, a temperature sensor, and a temperature controller. The circulating air flows evenly blow the hot air from the heater to the conveyed workpieces, ensuring uniform hot air in the drying box, avoiding uneven heating of the surface of the object, and speeding up the water-free drying of the workpiece.

Four, electrical control system

It adopts automatic control by relay or power regulator, and all electrical components used in the equipment adopt accessories that meet international standards. Emergency stop buttons can be set at the inlet and outlet ends to prevent accidents and failure to stop in time and improve the safety performance of the equipment. The electric control cabinet is equipped with two-color lights to indicate the normal operation and failure of the equipment.

Product parameter

PRODUCT PARAMETERS

1. Material size: according to customer requirements

2. Wind direction: horizontal air supply, circulating heating

3. Conveying direction: right into board and left out board

4. Working temperature: room temperature~150℃

5. Control temperature: 150±2℃

6. Total power: 3-phase 380VAC 109KW

7. Total exhaust air volume: 164CMM/Min

8. Material: The outer shell is made of high-quality cold-rolled sheet, and the inner cavity is made of galvanized sheet

9. Thermal insulation cotton: The furnace wall adopts Fiber Glass thermal insulation cotton

10. Thermostat: digital thermostat (0 to 299℃ working temperature display)

11. Current display: pointer type current display

12. Circulating air transport: HP 3-phase 380V AC for internal circulating air transport

13. Circulating air volume: 30~40 Cycle/min

14. Time switch: 999 minutes time switch

Send Inquiry