Secondary vulcanization oven

Product description

The secondary vulcanization oven, also known as vulcanization oven, post-vulcanization oven, is a hot-air circulating constant temperature oven designed for use in vulcanized or cured products. The oven process temperature is about 200 degrees, mainly used in automotive rubber and plastic parts, natural rubber products, synthetic rubber parts, silicone parts and so on. The equipment is equipped with hot air self-circulation, precise temperature control, and rapid air extraction device to accelerate the exhaust gas in the box.

[ Basic parameters ]

Size: Customized on demand

Material: Externally shaped with 1.2mm thick stainless steel.

Temperature uniformity: ±3 °C (no-load constant temperature 20 minutes test)

Working temperature: normal temperature - 200 ° C (temperature adjustment setting)

Temperature control accuracy: ±1 °C power supply voltage: 380V/220V, 50HZ

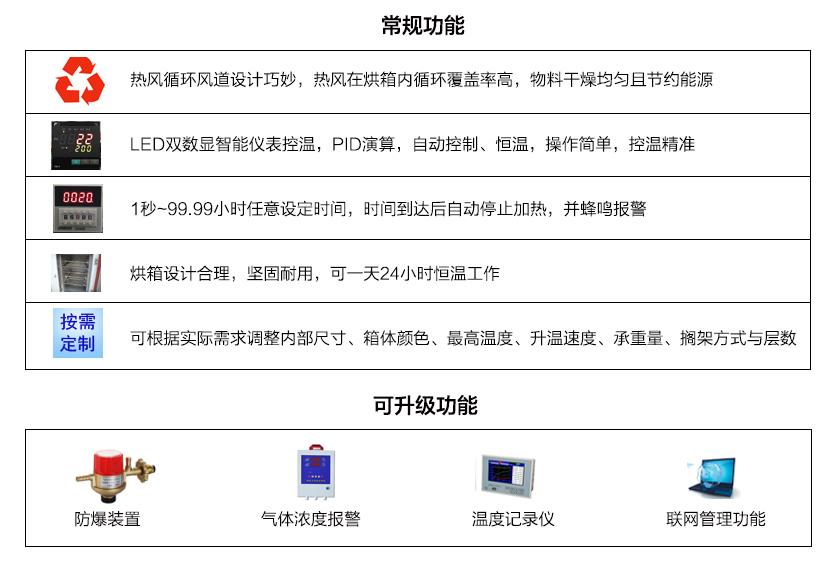

Temperature control mode: PID intelligent temperature controller (Yudian), relay / SSR solid state output heating equipment: heated by stainless steel heating tube, service life up to 30,000 hours or more air supply device: high temperature long axis motor, multi-wing configuration Centrifugal blades, forcing hot air to circulate rapidly, thus obtaining a uniform temperature exhaust device: Axial flow exhaust motor, top mounted, quickly extracting the vulcanized gas in the tank, automatically setting the pumping and stopping time timing mode: 0-999 minutes timer (SKG ), start timing / constant temperature timing is optional.

Control and safety: PIH+SSR solid state and AC contactor control output, high temperature control accuracy; simultaneous configuration of leakage protection, motor overload protection, over temperature protection (SKG).

Send Inquiry