Automated Tunnel Oven

Product description

FeaturesPRODUCT FEATURES

With rich experience in automation and oven design, Shenzhen Yihexing is able to provide excellent design and production services on customized automated tunnel ovens.Automated Tunnel OvenMainly used in metal electronics, packaging and coating, plastic leather, mobile phone accessories, auto parts, radiators, accessories, cosmetic containers, advertising paper, silicone rubber and other industries. It has the advantages of fast heating, simple operation, uniform heating of products, sustainable Baking products and other characteristics. It can be produced with the workshop assembly line, and the baking temperature, conveying speed and time can be adjusted according to production needs. The production efficiency is greatly improved.

YihexingAutomated Tunnel OvenFeatures

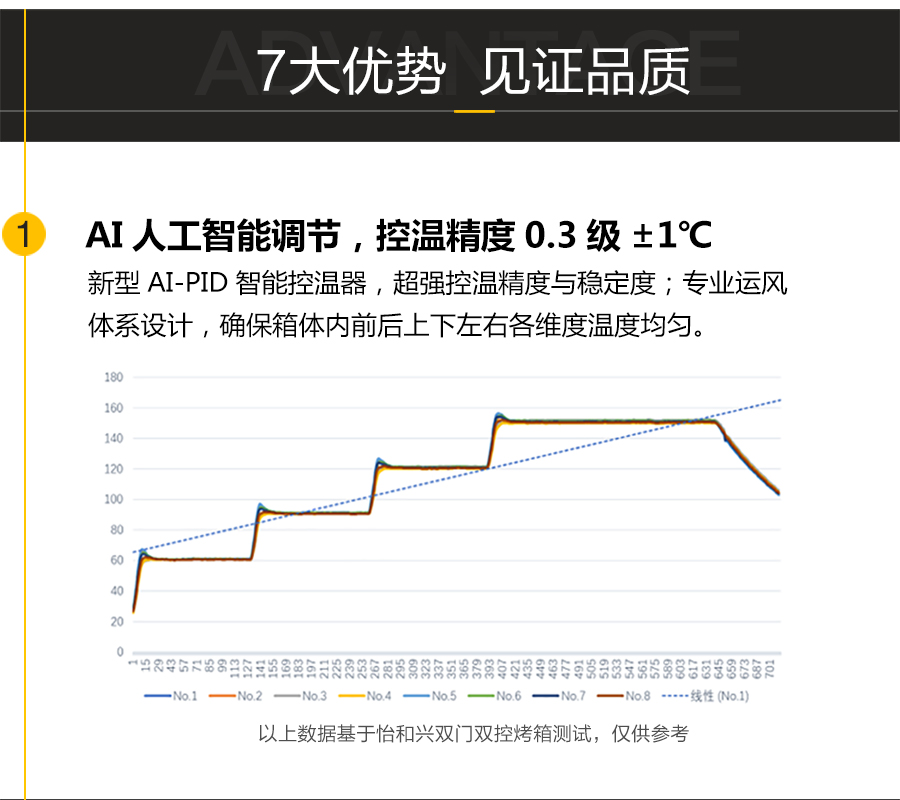

1. Using Japan's Omron temperature controller, PID automatic calculation, LED display, with SSR high-power thyristor output, can accurately control the accuracy of temperature;

2. The fully automatic assembly line oven adopts programmable controller, using software to change the control process, automatic control technology, convenient, simple, and flexible control. The high-precision, intelligent, and humanized structure is easy to operate and greatly improves productivity.

3. Conveyor belt frequency control, stable and adjustable conveying speed; equipped with conveyor belt anti-offset device, conveyor belt tension can be adjusted.

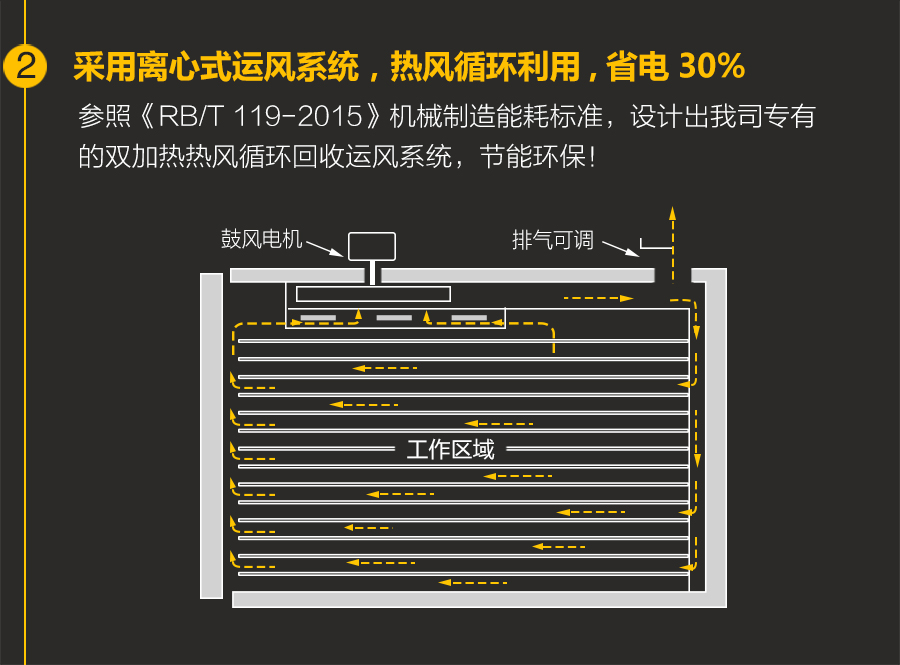

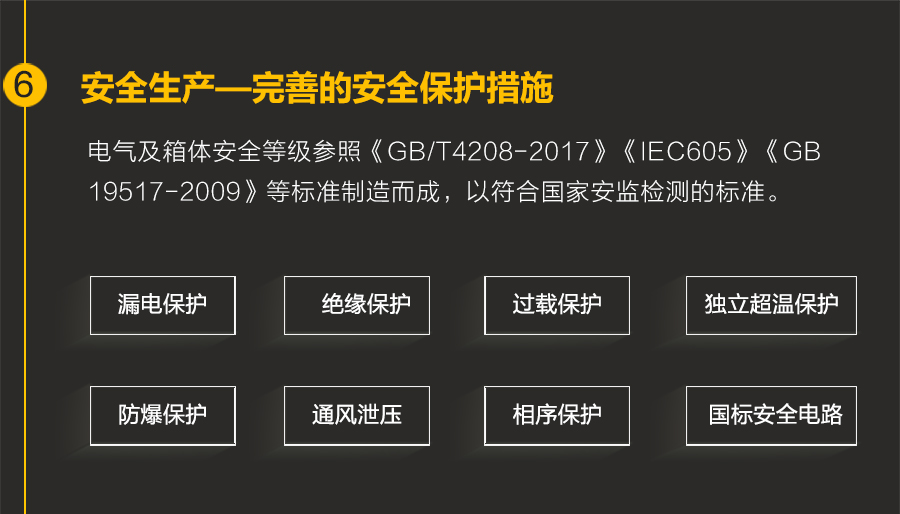

4. When the actual detected temperature exceeds the set value of the over-temperature protection thermostat, the heating power supply will be automatically cut off, which plays a double protection function, and is equipped with a variety of safety devices, so it can run continuously for a long time, saving energy, saving electricity, and protecting the environment. Strong safety performance.

5. The inner box is made of 1.5mm thick SUS304 stainless steel, and the outer box is made of 1.5mm thick cold-rolled steel plate, which has the characteristics of clean and dust-free, anti-rust, corrosion-resistant and good performance.

Options

Additional Thermocouple Measurements

Temperature recorder (paper or paperless)

Dedicated control system

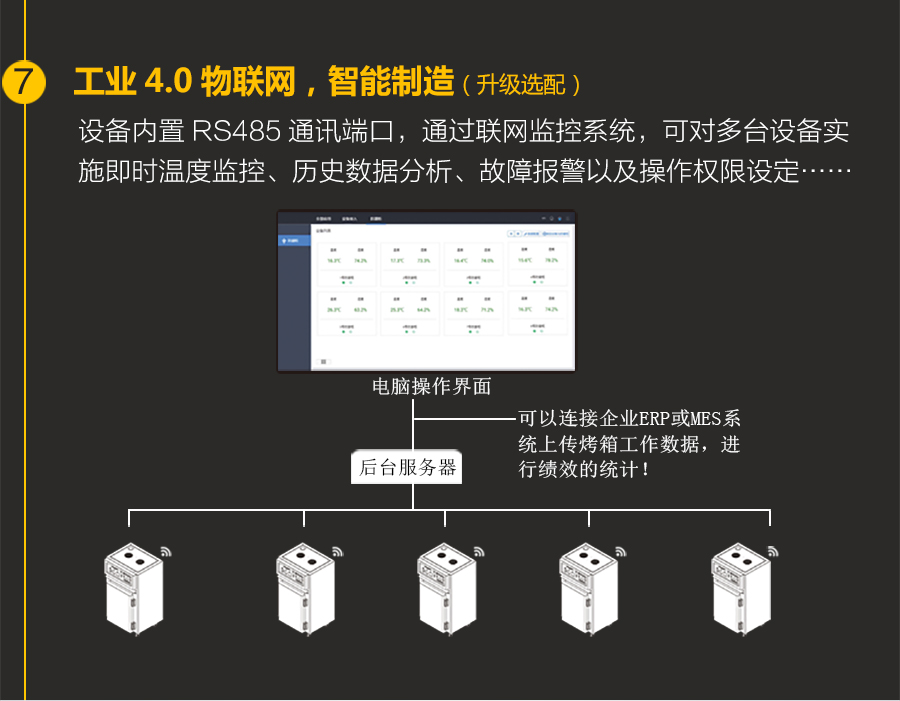

Programmable controller, Ethernet and USB communication

Cleanroom packaging for shipping and installation

Data logging and trends

Nitrogen system

RS232\/RS485 communication converter

application

Ageing

test

curing

dry

Solvent, Coating and Paint Care

stress relief

Application industry

Aerospace

car

Military industry

electronic product

research and development

rubber and plastic

semiconductor

telecommunications

Optical Communication

After-sales service

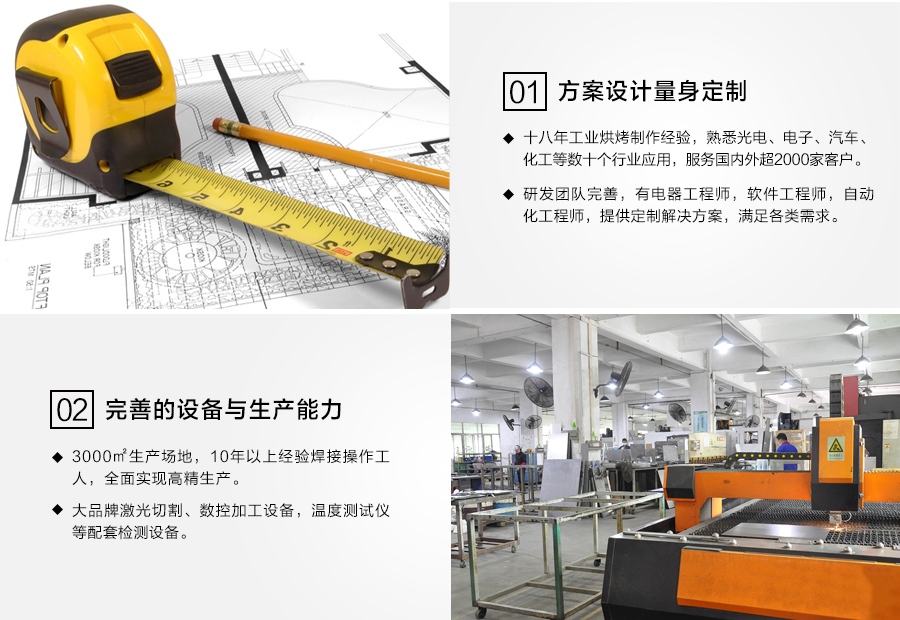

Installation and thorough training of staff are key to ensuring the proper functioning of your equipment. Jardine offers a variety of equipment installation and training options to ensure your equipment has a long productive life. Remote instruction, via email, instant messaging apps, phone , face-to-face video, on-site coaching support are all available for a variety of customers.

core configuration

CORE CONFIGURATION

Send Inquiry