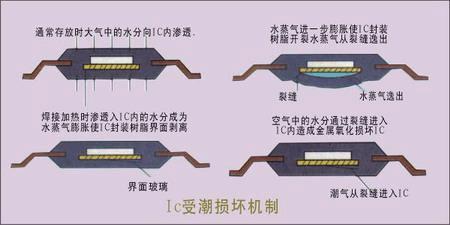

According to statistics, more than a quarter of industrial manufacturing defective products are related to moisture hazards every year. The semi-finished product in the package is between the next process; before and after the PCB package and between the power supply; the IC, BGA, PCB, etc. after the unpacking but not used up; the device waiting for the soldering of the soldering furnace; Devices; unpackaged finished products, etc., are subject to moisture hazards. For the electronics industry, the hazard of moisture has become one of the main factors affecting product quality.

As the microelectronics industry rapidly develops toward high integration and miniaturization, it also places high demands on the storage and storage of moisture sensitive devices in the production process. The International Printed Circuits Committee has established standards IPC/JEPCE-033B that specify the requirements for various MSD packaging and storage and shop life resets.

In recent years, more and more manufacturers and R&D companies have begun to adopt various methods to prevent the influence of moisture on devices and materials, thus avoiding the impact on the device itself and product quality. Among them, various types of dehumidification cabinets/drying cabinets/low humidity cabinets/nitrogen cabinets/etc. are currently more effective methods.

Yihexing moisture-proof cabinet adopts ultra-low humidity technology, and can realize networking of multiple moisture-proof cabinets. Through the networked system, the temperature and humidity of multiple moisture-proof cabinets can be monitored at the same time to accurately grasp the temperature and humidity changes in each cabinet. It can properly solve various non-performing rate problems such as air welding, oxidation, and bursting caused by BGA, IC, LED, CCD, QFP, and SOP adhesion in the SMT/packaging test/PCB/LED industry.