The manufacturing industry of informationization + automation integration is intelligent manufacturing. Intelligent manufacturing technology is based on advanced technologies such as modern sensing technology, network technology, automation technology, and anthropomorphic intelligent technology. Through intelligent perception, human-computer interaction, and decision-making. And the implementation of technology to achieve the design process, manufacturing process and manufacturing equipment intelligence, is the deep integration and integration of information technology, intelligent technology and equipment manufacturing technology.

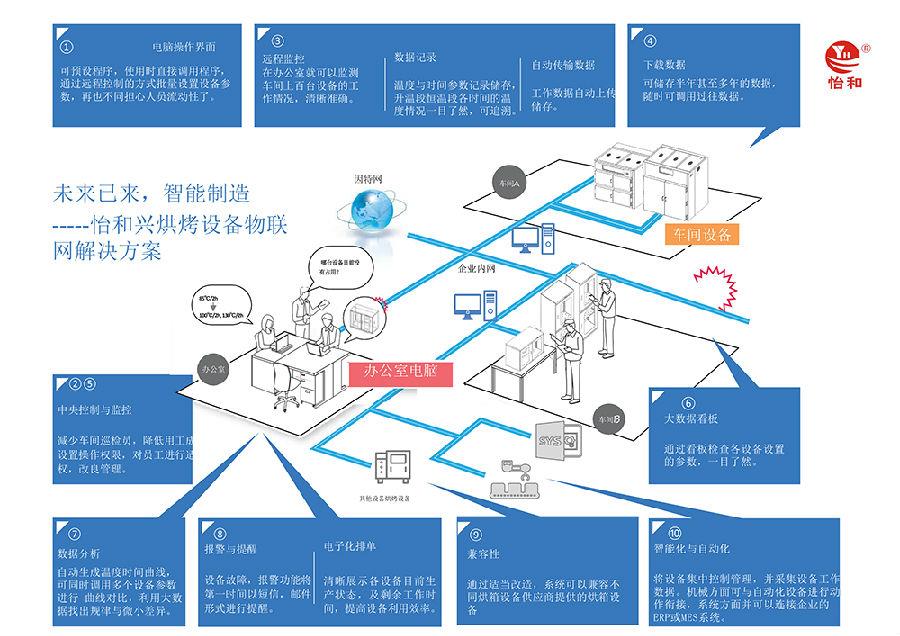

For intelligent manufacturing, the meaning of "Industrial Internet" is to clarify the three components of intelligent manufacturing: smart devices, intelligent systems, and intelligent decision-making. Through the integration of basic elements, Industrial Internet combines “big data” with machine-based analysis methods.

How to manage and analyze real-time data, and the system's analysis of production status is constantly improved. The machine's analysis method brings new dimensions, allowing analysis and "big data" toolset to be integrated, enabling the industrial Internet to use historical data to form certain Experience and combine real-time data for intelligent analysis. After digital smart devices, systems, and decisions are combined with actual machines, facilities, fleets, and networks, the Industrial Internet creates tremendous power and unlocks all of its potential. Thus, the benefits of increased productivity, reduced costs and reduced waste emissions will drive the entire industrial economy.

Intelligent devices use advanced sensing components, controllers and management software to connect machines (machine tools), facilities and networks, through the organic combination and coordination of these devices to achieve intelligent production.

Yihexing industrial oven fully realizes automation from data collection to data classification analysis, centrally manages equipment, collects equipment work data, and can connect with enterprise ERP or MES system to help enterprises realize lean management and help enterprises build intelligent manufacturing system.