Flat Bottom Precision Industrial Oven

Product description

FeaturesPRODUCT FEATURES

Industrial ovens designed and produced by Shenzhen Yihexing are used in different industrial sectors, especially for heat treatment applications up to ±250 degrees Celsius. Whether in standard or customized versions, industrial ovens provide the best possible thermal efficiency and are extremely convenient. Use and high level of operational safety, ideal for burn-in, chip hardening, drying, preheating, curing and component testing. With custom upgrade capabilities, these cart-type industrial ovens can also be used for tasks such as paint baking, plastic curing, varnish baking Baked, sterilized, rubber, silicone and epoxy curing applications. The cart type provides a fast and efficient method of loading and unloading. Single door, double door, 3 door, 4 door carts can match any product load.

Features

The shell is made of 1.2mm thick cold-rolled steel plate and fixed type

External paint is white powder coat for long-lasting corrosion protection

Trolleys with stainless steel pallets, each pallet has a load capacity of more than 50kg

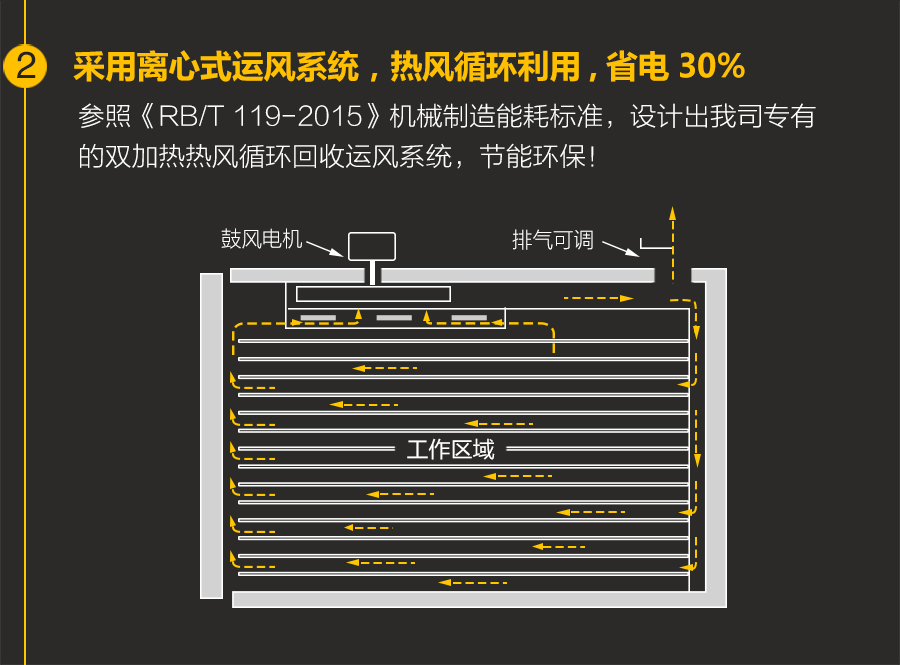

Adjustable air exchange system that allows fresh air to flow into the oven and exhaust air to leave the oven

Aluminum silicate insulation ensures that the surface temperature of the cabinet is safe and not hot

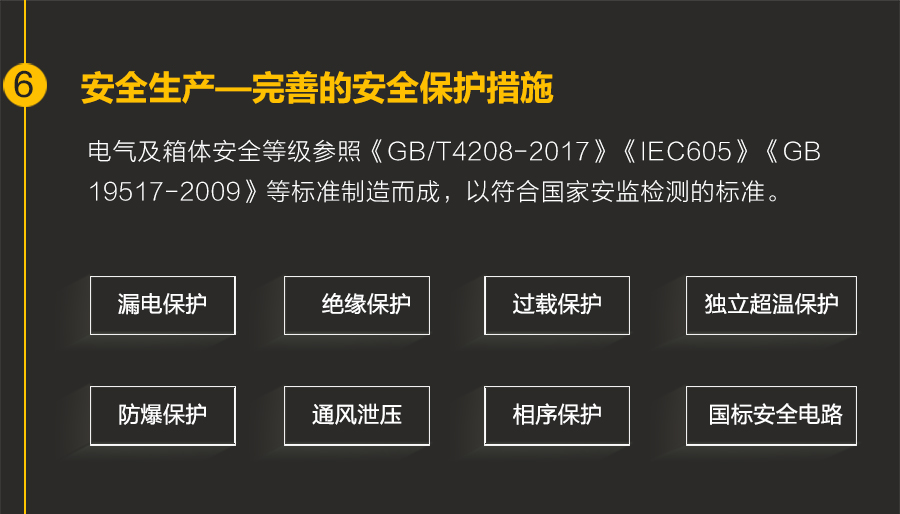

Double over-temperature protection, safer and more reliable

Circuit breakers providing ground fault protection as standard

Durable and sturdy design and manufacture, even if it works 24 hours a day, 365 days a day

Large capacity horizontal air recirculation system and electric heating system for temperature uniformity of performance

Outstanding reliability and performance ratings

Optional function

Additional Thermocouple Measurements

Temperature recorder (paper or paperless)

Dedicated control system

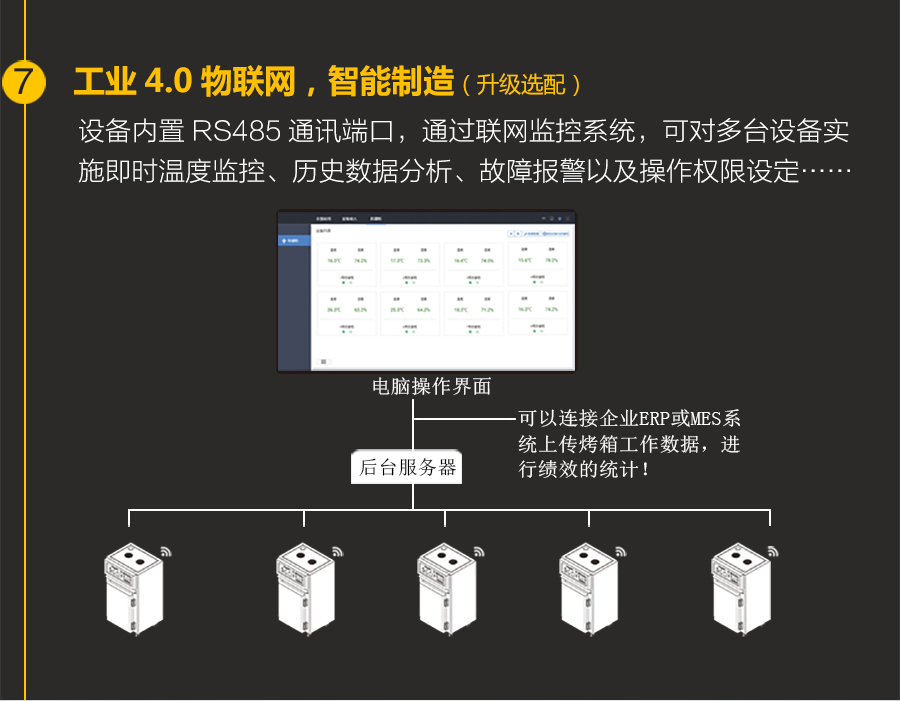

Programmable controller, Ethernet and USB communication

Cleanroom packaging for shipping and installation

Data logging and trend analysis

RS232\/RS485 communication converter

24 hour, 7 day digital process timer

Super heavy-duty trolley

application

Ageing

test

curing

dry

Solvent, Coating and Paint Curing

stress relief

industry

Aerospace

car

Military industry

electronic product

research and development

rubber and plastic

semiconductor

telecommunications

Optical Communication

Customized service

Our custom ovens are designed and manufactured to the exact specifications and heat treatment requirements of our customers. Check out examples of these products to see the wide range of industrial heat treatment systems we supply and manufacture for our customers. We are committed to providing high quality, comprehensive, efficient A low-maintenance oven operating system that accepts specific workspace sizes, materials, viewing windows, test holes or exterior color.

We also provide thermal testing and analysis of your product to ensure a precise oven design for your specific application. If you have a specific standard or specification that must be met, please contact us with your requirements so we can ensure the equipment designed, tested and tuned to meet these requirements.

Product parameters

PRODUCT PARAMETERS

model | GM-DKX-01 | GM-DKX-02 | GM-DKX-03 | GM-DKX-04 |

Internal dimensions height x width x depth | 1550x1200x1000 | 1600x1200x950 | 1200x1300x800 | 1350x1260x1050 |

External dimensions height x width x depth | 1830x(1500 plus 235)x1140 | 2100x(1480 plus 235)x1100 | 1620x(1600 plus 235)x950 | 1880x(1560 plus 235)x1200 |

capacity | 1860L | 1820L | 1250L | 1780L |

heating power | 12kw | 12kw | 9kw | 12kw |

temperature range | Room temperature. Plus 20200 degrees Celsius | |||

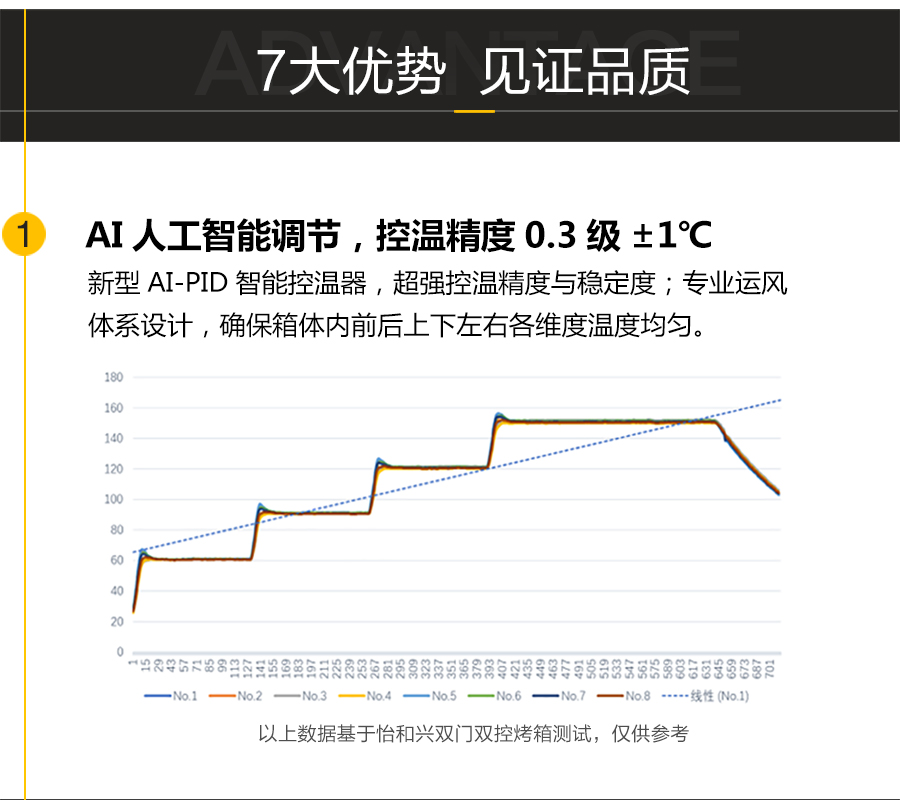

control precision | ± 1.0 degrees Celsius | |||

Temperature distribution accuracy | ±4 degrees Celsius (at 100 degrees Celsius), ±8 degrees Celsius (at 150 degrees Celsius) | |||

temperature rise time | About 30min (room temperature,→150 degrees Celsius) | |||

Operation function | Optional fixed temperature or programmed operation | |||

power supply | 3Mutually380V | |||

core configurationCORE CONFIGURATION

Send Inquiry