Oxygen-free nitrogen oven

Product description

FeaturesPRODUCT FEATURES

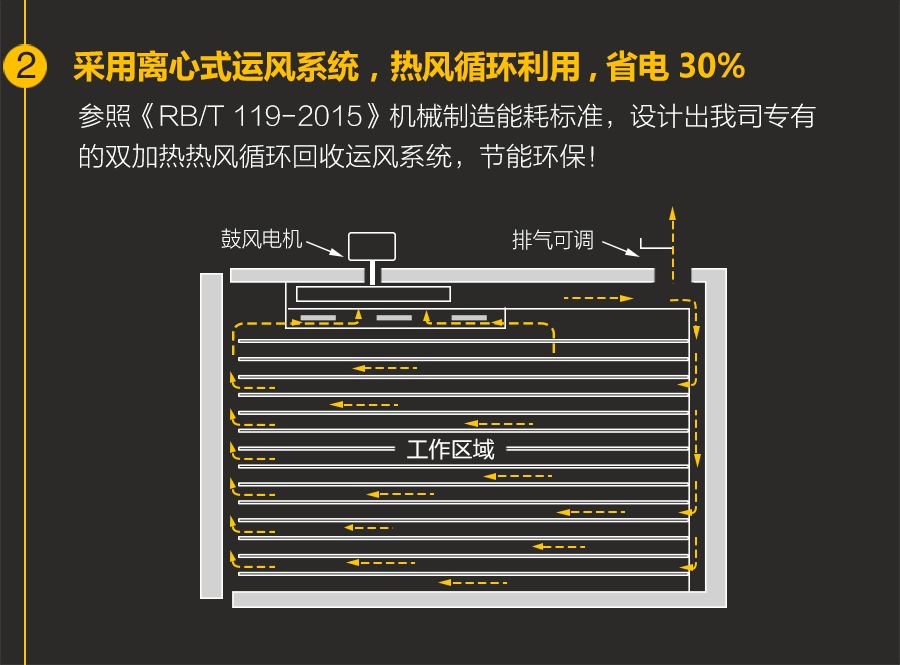

1. The box body is made of ceramic fiber for heat preservation, which has the characteristics of fast heating and energy saving.

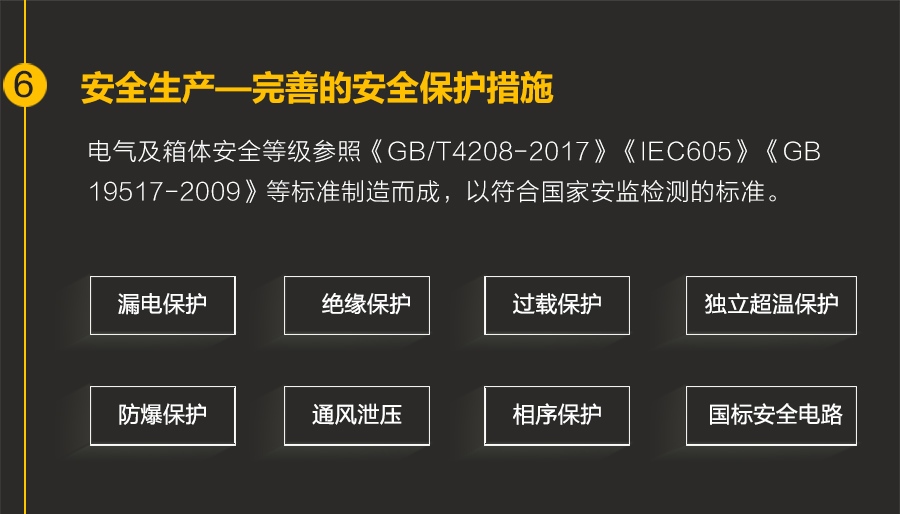

2. The inner tank is fully welded, and the pipeline is welded with seamless stainless steel pipe fittings. The oxygen concentration can reach 20PPM.

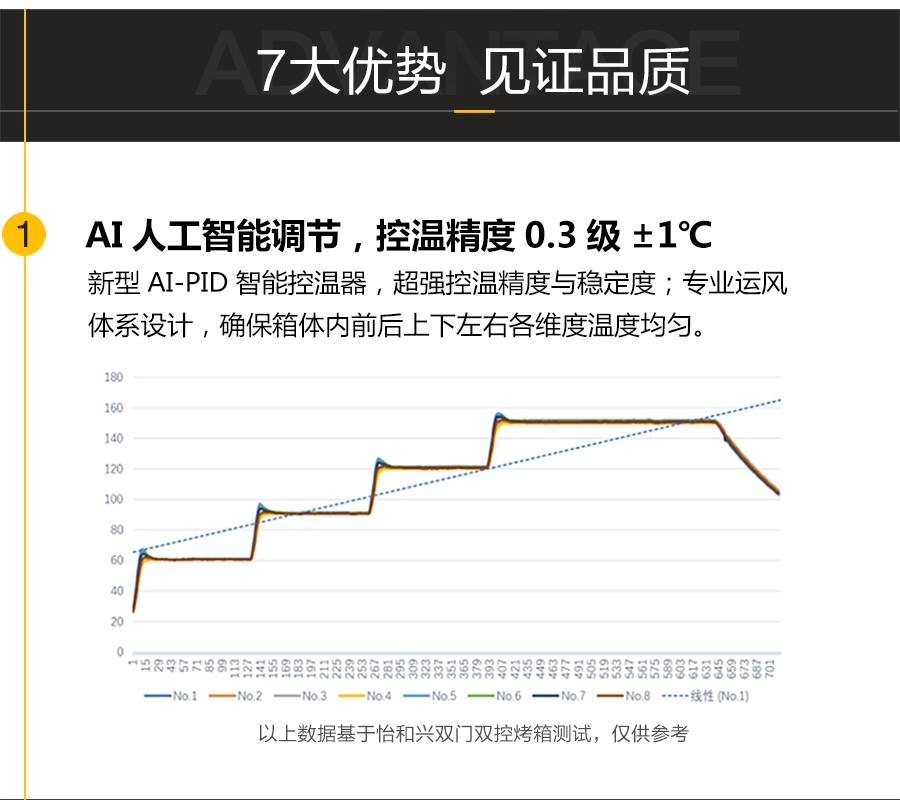

3. Using forced ventilation, there is an air duct in the oven, the temperature uniformity is 1.5 ℃%, the material is dried uniformly, and the suction port is glass fiber filter to ensure the cleanliness requirements.

4. Imported temperature control system, PID automatic calculation, temperature control accuracy ±0.5℃.

5. Double flow meter nitrogen saving system, double delay nitrogen filling control, greatly save nitrogen consumption under anaerobic and low oxygen environment.

The oxygen-free oven can achieve an oxygen content of ≤50ppm. Due to its airtightness and the distribution of nitrogen gas, the design of the air duct, and the design of the exhaust position are all designed through digital and analog simulation.

6. The door of the oxygen-free oven adopts a double-sealed structure, which can also realize the functions of rapid reduction of oxygen and rapid temperature rise.

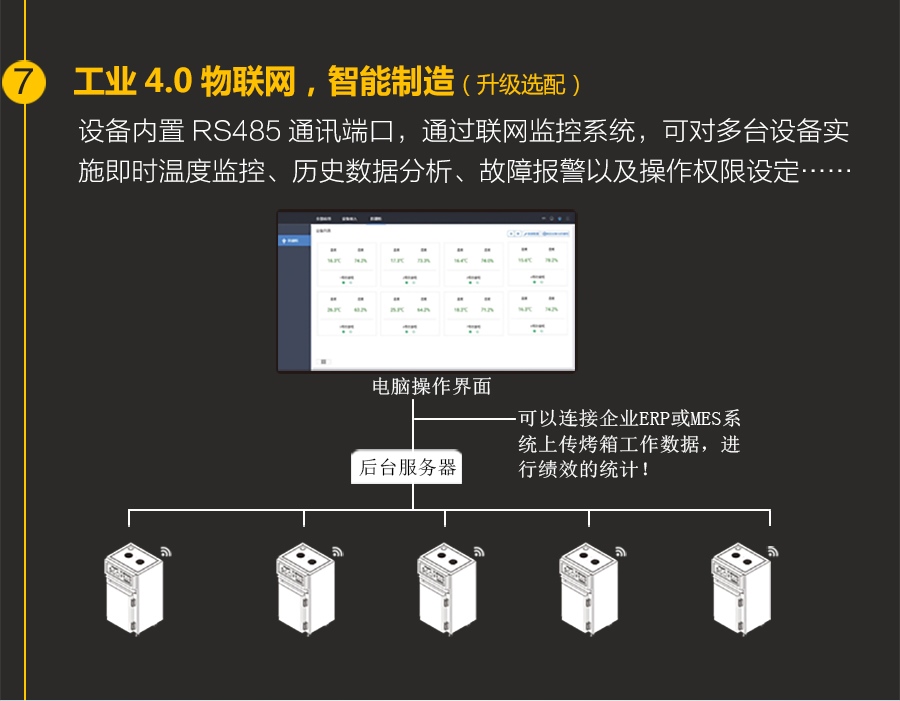

7. Optional accessories

①Multi-point temperature measurement, viewing and recording function; ②Oxygen content analyzer; ③Network function; ④HEPA high efficiency filter; ⑤Quick cooling system

8. It can adapt to the production needs of Industry 4.0.

Core configuration

CORE CONFIGURATION

Send Inquiry