Custom Automated Tunnel Oven

Product description

FeaturesPRODUCT FEATURES

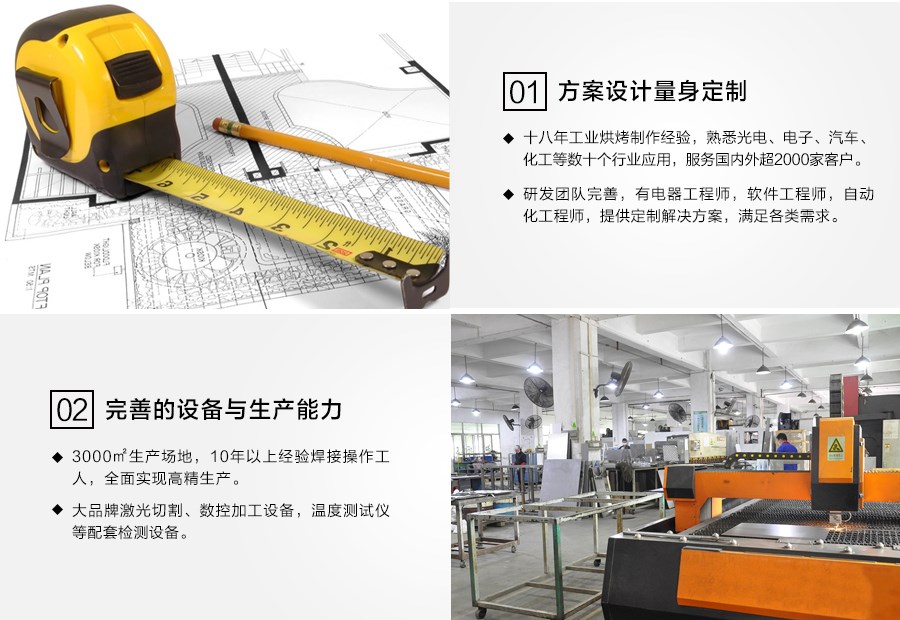

With rich experience in automation and oven design, Shenzhen Yihexing is able to provide excellent design and production services on customized automated tunnel ovens. Tunnel ovens, also known as tunnel ovens, adopt a modular design that enables customers to customize according to production requirements. Flexibility to add upgrades as needs change. Standard and custom features are available in multiple sizes and temperature ranges.

Tunnel ovens can be designed with heating and cooling sections for continuous processes and can accommodate high-intensity and high-volume production applications. A variety of conveyor ovens are available to meet customer application requirements. Common options include variable conveyor speeds Control, heating temperature range, automatic loading or unloading of fixtures or temperature uniformity.

Our experienced team has designed additional application capabilities for a variety of processes, including tempering, curing, preheating, drying, heat shrinking and thermoforming.

Features

The shell is made of high-quality 1.5mm thick cold-rolled steel plate and fixed type

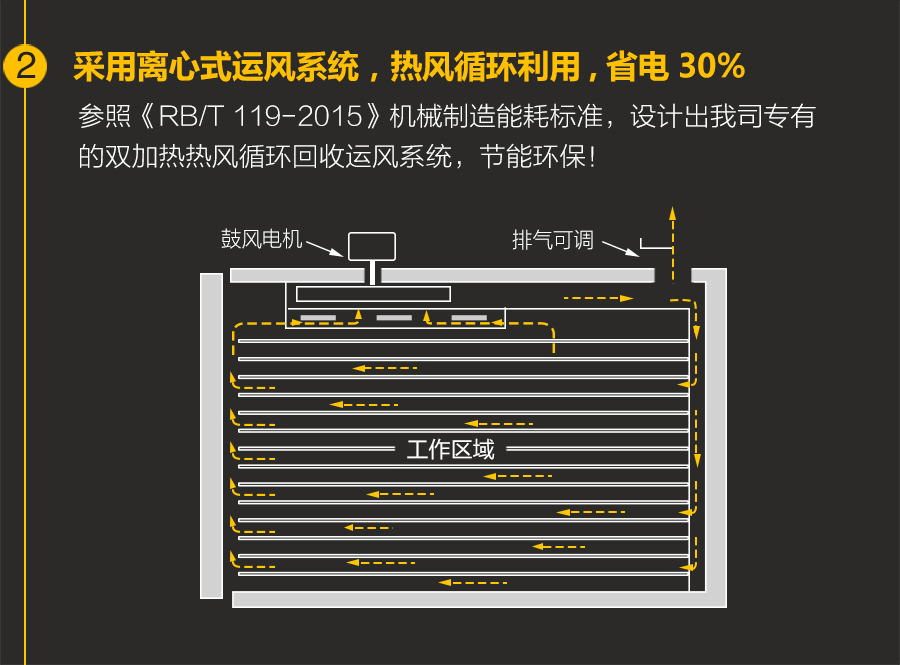

Horizontal and vertical conveying furnace design to maximize airflow

Custom designs for curing applications of materials such as plastics, varnishes, rubbers and epoxies

Various configurations, including flat conveyor belt, PTFE conveyor belt, carbon steel conveyor chain, etc.

Advanced Digital Controller

Optional items such as access doors, illuminated viewing ports and beam sensors

Temperature range from 100 degrees Celsius to 500 degrees Celsius

Dimensions can be customized according to demand and output

Automatic lifting or loading function based on requirements and line status

Baked on the surface of white powder, durable anti-corrosion

Adjustable air exchange system that allows fresh air to flow into the oven and exhaust air to leave the oven

Aluminum silicate insulation for safe cabinet skin temperature

Excellent reliability and performance ratings

Options

Additional Thermocouple Measurements

Temperature recorder (paper or paperless)

Dedicated control system

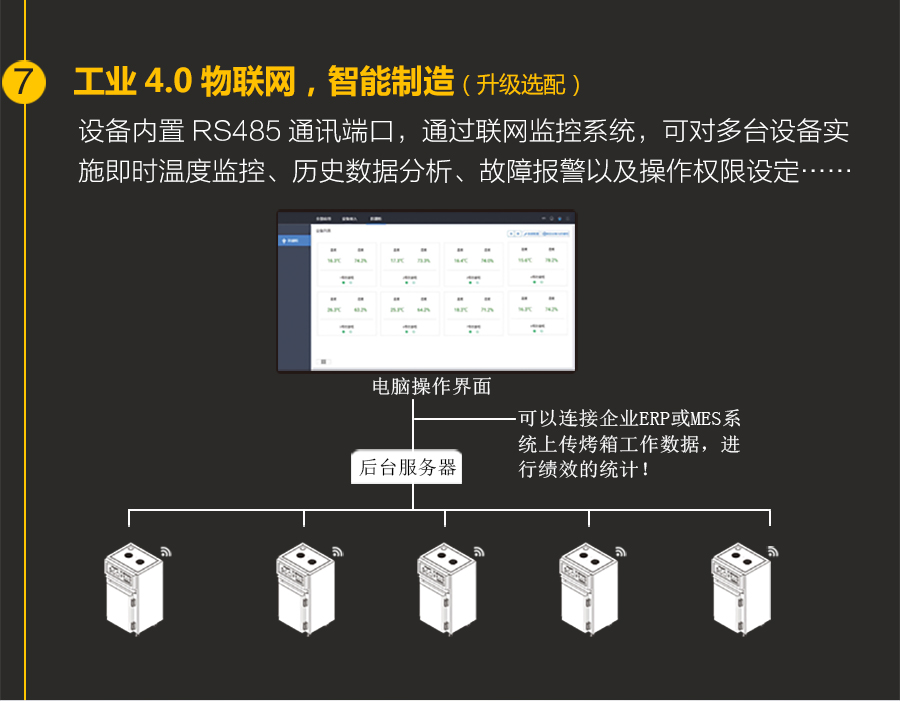

Programmable controller, Ethernet and USB communication

Cleanroom packaging for shipping and installation

Data logging and trends

Nitrogen system

RS232\/RS485 communication converter

application

Ageing

test

curing

dry

Solvent, Coating and Paint Care

stress relief

industry

Aerospace

car

Military industry

electronic product

research and development

rubber and plastic

semiconductor

telecommunications

Optical Communication

After-sales service

Installation and comprehensive training of staff are key to ensuring the proper operation of the equipment. Jardine has a comprehensive after-sales service, offering a variety of installation and training options to ensure a long productive life for your equipment. Remote guidance, via email, instantly Communication apps, phone calls, face-to-face video, live coaching support are all available for a variety of clients.

core configuration

CORE CONFIGURATION

Send Inquiry