Multi-door multi-control photoelectric oven

Product description

LED oven is specially used for the drying box of LED photoelectric components. It has a unique multi-door multi-control design. Each box is independently controlled, which is convenient for a variety of products to be produced or tested on the same machine, reducing costs and facilitating energy saving. This product is also suitable for the drying process of aging and curing of other electronic components.

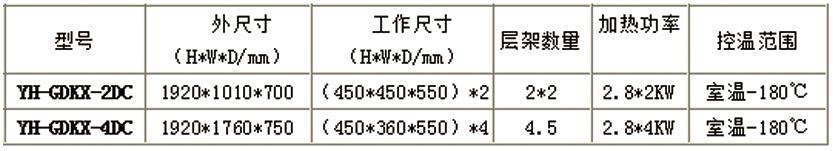

Multi-door single control photoelectric oven specification configuration:

1. Box part: Unique multi-door multi-control design, open one of the doors arbitrarily, no temperature difference effect on other boxes, suitable for a variety of process processing. The outer casing is made of 1.5mm thick cold-rolled steel plate, and the surface is sprayed with high-temperature spray paint to resist corrosion and rust. Each layer of the oven is equipped with a handle, so that each layer of the tray can be taken out independently. The high temperature sealed silicone strip is added around the door to make the temperature outside the furnace not hot. The shelf trays are made of stainless steel, and each shelf can be taken out independently. The bottom of the oven is equipped with movable casters for easy access to the oven.

2, the inner part: the inner liner is made of 1.0mm thick SUS304# stainless steel plate, the inner liner is covered with 100K thick high temperature resistant silicic acid heat insulation rock wool, built-in air circulation trough, circulating horizontal air transport, making the furnace temperature more uniform .

3. Heated part: imported stainless steel heat sink type heat pipe on both sides of the oven air trough, unique heat insulation device design, circulating large air volume forced horizontal air transport, equipped with intake and exhaust port valves, adjusting intake and outlet ports The amount of air flow makes the temperature inside the furnace more uniform.

4, electrical parts: power supply 380V, three-phase five-wire system, power 5.5KW, using imported microcomputer intelligent digital display temperature controller. Room temperature - 200 ° C can be adjusted arbitrarily, the temperature rise to 150 ° C takes about 10-20 minutes. With PID self-tuning, automatic constant temperature function, accurate temperature control, 0---999 minutes arbitrary timing control.

Features:

1. The outer casing is made of 1.2mm thick cold-rolled plate, and the surface is sprayed with high-temperature spray paint to prevent rust and corrosion.

2. The whole machine is assembled according to CE/3C and other certification standards, in line with the safety standards of the national safety supervision and electric baking equipment industry.

3, circuit design strong and weak electrical separation, double-line double protection, creative use of electric insulation device, for personal protection, product protection is more secure.

4, the original balanced dual heating air transport system, unique hot air circulation recovery mode, more than 30% energy saving than ordinary ovens.

5, electrical accessories all use the first-line brand, PID calculation of the temperature control system and over-temperature protection device, intelligent constant temperature, small temperature difference, suitable for long and short baking of different manufacturers and products.

6, using digital display PID temperature controller, with over-temperature deviation protection and timing function, accurate and reliable temperature.

7. The shelf trays are welded by stainless steel square tubes. Each layer shelf can be taken out independently. The spacing of the shelf and the number of shelves can be adjusted to meet different specifications. Four universal brake wheels and four locating cups are installed at the bottom of the oven.

8, using high temperature silicone seal, high temperature heating tube to do heating components, to ensure safety and long service life.

Scope of application: LED optoelectronic industry, lighting and lighting industry, electronic and electrical industry, PCB aging industry, hardware and plastics industry. . .

Send Inquiry