PCB refers to a printed circuit on a dielectric substrate that is designed according to a predetermined design to provide a conductive pattern between components. PCB is one of the important electronic components and is the support of electronic components. So, why do PCBs need to be baked before SMT?

1. The PCB is a moisture sensitive material under the lead-free process condition. If moisture-proof packaging is not carried out, the moisture absorption after three months may cause delamination (foaming) during PCB soldering.

2. After baking, the pcb board reaches a certain temperature, the flux can be better combined with the components and the pads, and the welding effect will be greatly improved.

3, in order to ensure that the water content of the PCB is less than 0.1%, the drying process of 125 °C\5h must be taken before the SMT is put on the line. The baked PCB board should wait until it is cooled before it can be put on the line.

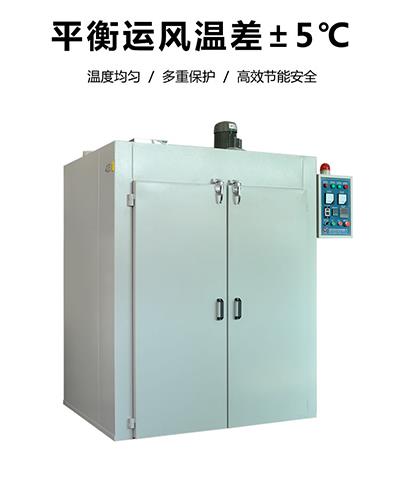

PCB special drying oven is a kind of oven, mainly used for baking, drying, preheating, tempering, aging, etc. of PCB, rubber keyboard, coil, hardware, chemical, auto parts and so on. The principle of the PCB drying oven is a special oven developed for the electrical connection and support of electronic components of printed circuit boards. Applicable to the aging and drying of printed boards, flexible circuit boards, computer mobile phone cables, etc. The PCB oven adopts flexible and adjustable shelf, and the layer height is adjustable. The microcomputer intelligent PID control technology is combined with the SSR solid state relay output to accurately control the temperature. The internal hot air circulation, the baked goods are evenly heated, the heating time is fast, and the temperature is stable. .

PCB baking temperature and time setting

(1) If the pcb seal is unsealed for more than 5 days within 2 months, the temperature is 120±5°C for 1 hour;

(2) PCBs with a manufacturing date of 2 to 6 months, baked at a temperature of 120 ± 5 ° C for 2 hours;

(3) PCBs with a manufacturing date of 6 months to 1 year, baked at a temperature of 120 ± 5 ° C for 4 hours;

(4) The finished PCB must be processed within 5 days, and the unprocessed pcb needs to be baked for another hour to go online;

(5) PCBs that are more than one year old on the manufacturing date, baked at a temperature of 120±5°C for 4 hours, and re-sprayed to be on-line.