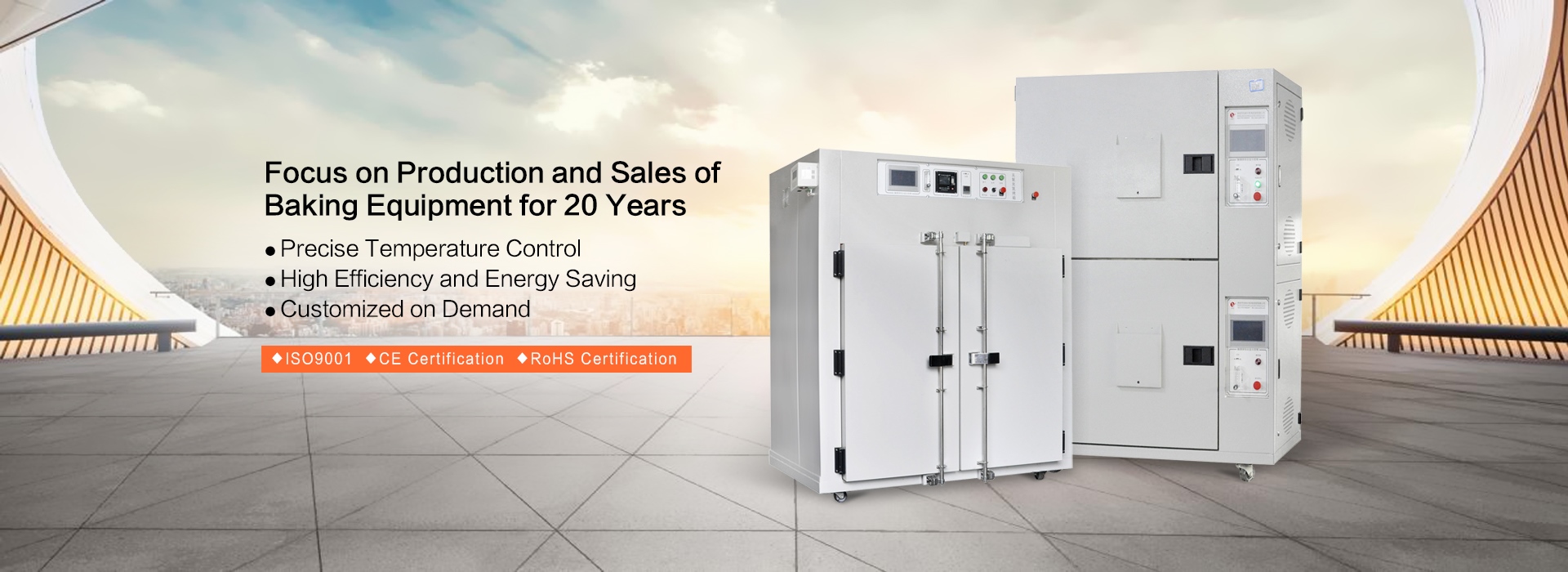

Spray screen printing oven

Product description

Spray screen printing oven is suitable for all kinds of plastic shell silk screen printing, plastic screen printing, glass printing, acrylic printing and other silk screen printing industry. Wire mesh high temperature oven heats the product through hot air circulation to accelerate the curing degree and firmness of silk screen printing products.

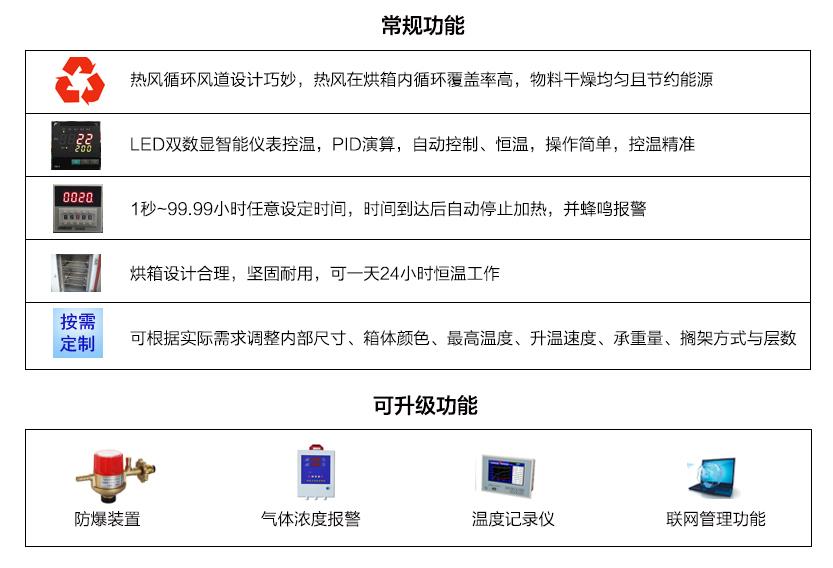

【Features】

Temperature range: room temperature -250 ° C, any adjustable

Temperature control: intelligent PID self-regulating thermostat with control accuracy of ±1 °C, with SSR solid state relay output, can accurately control the temperature inside the oven, so that the temperature uniformity in the oven is ±3 °C (no-load test)

Baking method: layered, cart type baking

Shape structure: front double door type, cart rail at the bottom of the tank (applying the ground treatment), the electric control box is placed on the right side for easy operation.

Protection device: over-temperature alarm power-off, leakage protection, alarm at the time, motor overload protection, phase sequence protection, control line fuse, no fuse switch and other electrical accessories. There is an explosion-proof door on the back of the oven.

Air transport system: the air is circulated around the furnace, the heat energy is well preserved, the temperature is uniform, the power saving is time-saving, the effect is high, the operation is convenient, the automatic constant temperature, and the timed baking.

Heating system: stainless steel heat sink heating tube, heating power: 12KW, total power: 13.5KW

Product advantages: uniform temperature, multiple protection, high efficiency, energy saving, environmental protection and safety

Customized according to customer requirements.

[Technical indicators]:

1, temperature range: normal temperature -250 ° C, adjustable thermostat

2, size: non-standard custom

3, heating rate: from room temperature to 200 ° C in about 30 minutes

4, thermal insulation performance: the outer wall temperature does not exceed 45 ° C (when the furnace temperature reaches 200 ° C)

5, temperature control accuracy: ± 2 ° C

6, temperature uniformity: ± 3 ° C%

7, the use of power: 380V/50HZ (three-phase five-wire)

Send Inquiry