As more and more companies have higher requirements for the reliability of electronic products, the potting of electronic products has become an indispensable process in the production process. We all know that the traditional manual glue filling operation is characterized by low output, long time-consuming, and error-prone, so the production efficiency is low, the scrap rate is high, and it is difficult to reduce labor costs. These problems can be easily solved by using a glue filling machine to complete the glue filling procedure.Glue filling machineThe main features are fully automatic, fast and high productivity. Because the entire glue filling process is carried out through pre-set procedures, one machine can complete the workload of several or even a dozen workers, thereby achieving the purpose of improving production efficiency, reducing waste rate and reducing costs. The application of glue filling machine is also more and more extensive, which can be used in the dispensing process of auto parts, mobile phone keys, batteries, notebooks, coils, PCB boards, ICs, speakers, PDAs, LCDs, ICs and other products.

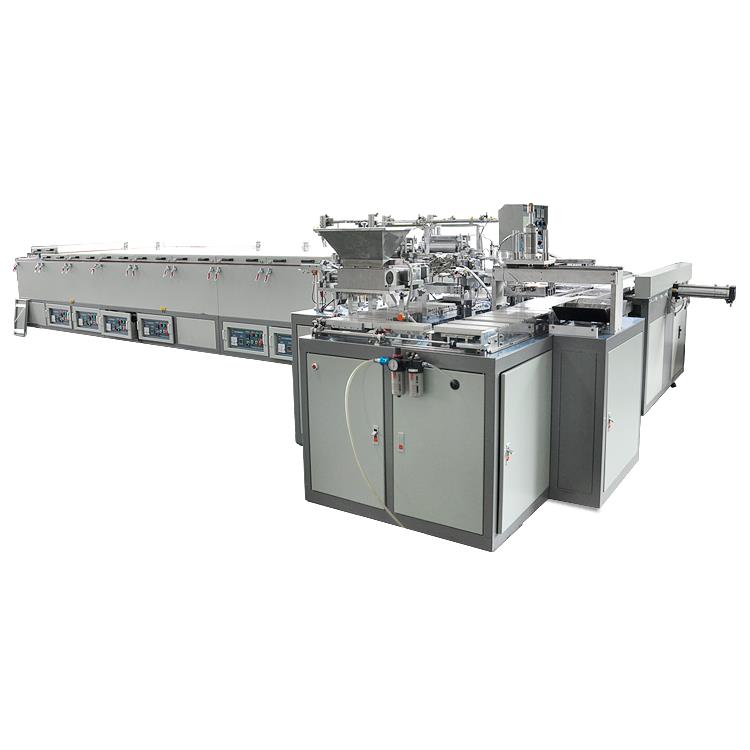

Yihexing automatic high-speed glue filling machine is an upgraded and customized intelligent glue filling production line, which realizes the functions of automatic identification of product model, automatic glue filling, automatic drying, and automatic reflow of tooling. The production line presets MES interface, which is convenient to realize the docking with the system and upload the data. The data covers the production quantity, defect phenomenon, equipment abnormal phenomenon, abnormal time and other data; optional bracket detection imaging system, taking pictures, automatically identifying product types and automatically calling out The glue program enters the glue filling area to take pictures of the later stage, automatically recognizes the glue filling path and performs automatic glue filling, the product is automatically dried, and the tooling is automatically reflowed without manual intervention, thus realizing intelligent production. Reduce the manpower input of the enterprise, liberate the labor productivity, speed up and improve the production efficiency and product quality of the enterprise.