The packaging and testing plant starts from the material (wafer), goes through the previous wafer surface filming and then the backside grinding (GRD)→wafer backside polishing (polish)→wafer backside filming (W-M)→wafer surface Film (WDP) → wafer baking (WBK) and other processes to package and test the chip. Semiconductor chip production workshops have strict production conditions, such as constant temperature and humidity, dust-free and clean, etc. Chips can only function normally in a suitable environment, and the normal environment around us cannot do this in most cases. One point, so packaging and testing are needed to protect the chip and create a good working environment for it.

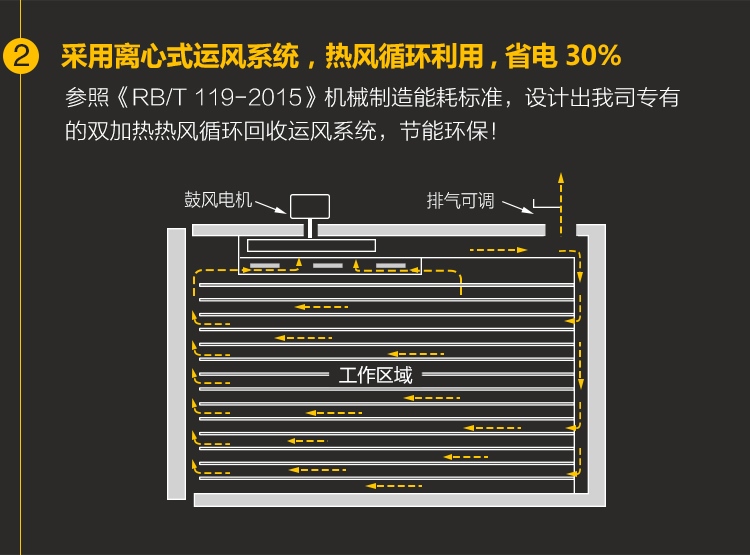

Yee Hing CleanIndustrial ovenIt is a special clean and dust-free drying equipment that provides a high-temperature purification environment. The air in the box is closed and self-circulating, and it is repeatedly filtered by a high-temperature high-efficiency air filter (class 100), so that the working chamber of the oven is in a dust-free state.

Clean ovenIt has the following characteristics and product tightness requirements. The studio material is made of SUS304 stainless steel plate, and the inner tank is fully welded by argon arc welding to prevent air from entering the oven and the fine dust generated by the machine itself, while saving inert gas. The external dust-proof treatment is made of SPCC steel plate through powder spraying, which is wear-resistant and does not drop dust and slag. The thermal insulation material is high-density ceramic fiber, which is energy-saving and thermal insulation. Layered structure design The height of the inner box is adjustable and can be taken out freely. The internal structure accessories are made of non-oxidizing and dust-free materials. The outer box structure of the drying box adopts a special sealed structure design to ensure that there is no cross-contamination with the clean room. The box has movable casters, which can be pushed and fixed at will. The built-in high-efficiency filter HEPA filter structure clean room and clean level below 100. Forced air circulation to ensure uniform temperature, optional nitrogen filling system, optional PLC+ HMI man-machine touch screen control system, with data output interface.