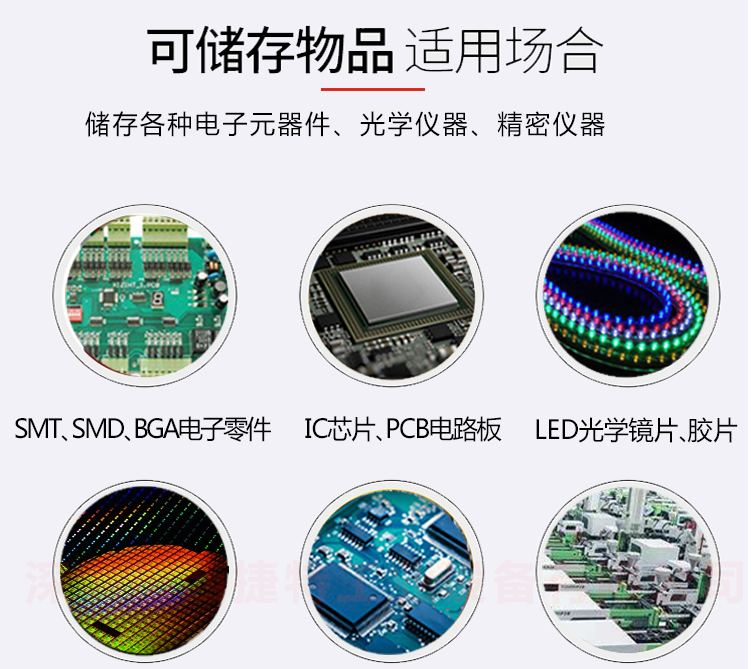

With the rapid development of science and technology, electronic products have penetrated into the scientific fields of optoelectronic materials and components, optical instruments, optical communications industry, optoelectronic displays, laser and laser applications, optoelectronic accessories and electronic components, SMT surface mount, semiconductor industry and other scientific fields. Because modern new equipment is equipped with a large number of electronic accessories and devices, these miniature electronic devices, integrated circuit boards, plug-in chips, small composite material modules and electronic components with specific functions, and these components are easily exposed to a relative humidity of 60%RH or more. In humid air, it is highly hygroscopic. Due to the poor storage environment, various accessories and components fail before being used, which seriously affects the reliability of the equipment. Therefore, improve the reliability of electronic components and various accessories, ensure the maintainability and integrity of the equipment, establish a dehumidification platform to meet the humidity environment requirements for the storage of various precision accessories and electronic components, and classify management according to the humidity range. Intelligent management is a top priority.

Application fields of Yihexing moisture-proof cabinet:

1. It can effectively prevent the damp and mildew caused by the stack of TFT-LCD glass substrates when the wafer or semi-finished product is in the unsealed state

2. It can prevent the oxidation of optical fiber K gold connector, bonding gold wire material, Leadframe copper material and other metal parts during the period

3. The electronic moisture-proof box can prevent the "golden finger" splashing tin caused by explosive exhaust of the PCB substrate before SMT placement during reflow.

4. It can effectively prevent the internal oxidation short circuit of IC (including QFP/BGA/CSP) integrated circuits and other components during storage, as well as internal micro-cracking, separation and delamination, and external "popcorn" phenomenon during welding.