Static electricity is the main physical factor that causes damage to sensitive components, components and equipment. When the components are exposed to an electrostatic field, most components are vulnerable to damage. Static electricity can often inadvertently break down or damage expensive electronic components and affect or lose their functions.

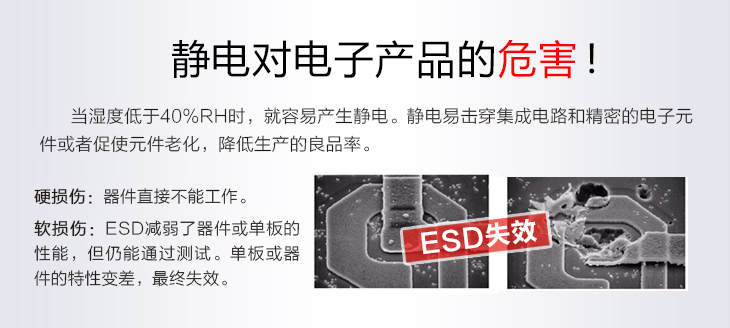

In the electronics industry, as the degree of integration becomes higher and higher, the inner insulating layer of integrated circuits becomes thinner and thinner, and the width and spacing of interconnecting wires become smaller and smaller. For example, the typical thickness of the insulating layer of CMOS devices is about 0.1 μm. The corresponding breakdown voltage is 80-100V; the insulating layer of VMOS devices is thinner, and the breakdown voltage is 30V. The electrostatic voltage generated in the manufacturing of electronic products, transportation, storage, etc. far exceeds the breakdown voltage of MOS devices, which often causes hard breakdown or soft breakdown (partial damage to the device) and makes the device invalid Or seriously affect the reliability of the product.

After carefully investigating the whole process of welding the LED light board, and measuring the static electricity of each link, we found the main station of static electricity;

1. The LED is imported from the anti-static bag into the material box 100V

2. Cut the LED pin to 100~200V (the discharge voltage of the scissors to the LED cannot be measured)

3. Throw the LED into the material box 800V

4. The LED is poured from the material box into an anti-static bag for packaging 800V

5. Pour the LED from the anti-static bag into the material box 300V

6. Take LED1000 from the material box

7. Take out the positioning light board 500V after welding

According to the characteristics of the above-mentioned main static electricity generating stations, after analysis, it is judged that the large area damage of the LED is mainly caused from two aspects: 1. Static electricity generated by vibration, friction, and collision. 2. Human body discharge. For the discharge of the human body, an anti-static wrist strap must be worn correctly, which can effectively guide the static electricity of the human body into the earth in time. In view of the above-mentioned situation, it is necessary to equip with anti-static and moisture-proof cabinets at the above main stations. It can not only achieve the effect of moisture-proof and low-humidity, but also eliminate static electricity, ensuring that electronic parts in low-humidity environments are protected from static electricity.