In the storage requirements of moisture sensitive components (MSD), it is clearly stipulated that electronic components must be protected from oxidation and moisture. According to the development of high-tech equipment, stainless steel nitrogen cabinets have emerged.

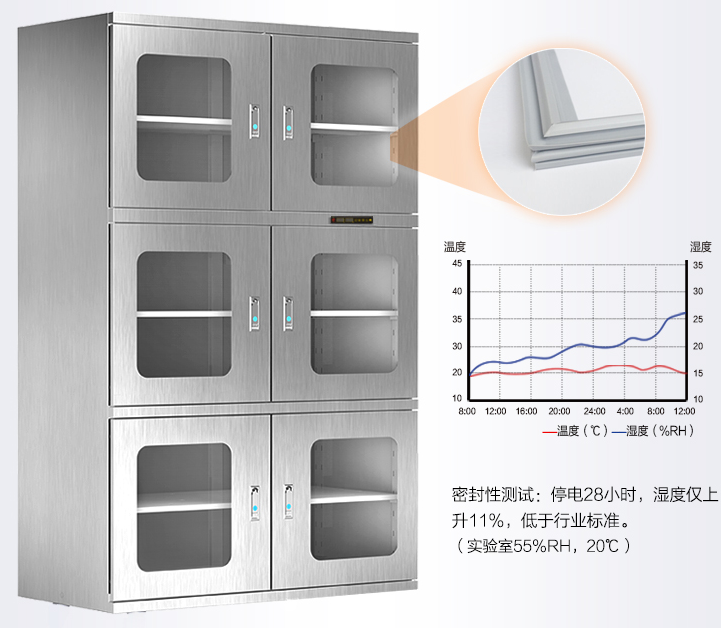

As an industrial equipment, the stainless steel nitrogen cabinet can meet the storage requirements for moisture-proof and anti-oxidation storage of various bga, ic, chip and other humidity-sensitive components. The nitrogen cabinet adopts stainless steel cabinet body, surface drawing treatment, high-strength cabinet body, splicing and fully sealed treatment to ensure low humidity effect, strong anti-corrosion and corrosion resistance, dust-free and clean, commonly used in purification workshops, pharmaceutical workshops, food workshops, aerospace industry.

The multi-functional stainless steel nitrogen cabinet mainly uses nitrogen to reduce humidity and prevent oxidation. It can monitor the concentration or humidity in the cabinet as needed. It can quickly provide a low-oxygen and low-humidity environment for LED, IC, LCD, crystal, PCB, and optical electronic components. , Chemicals, high-precision measuring devices and other industrial production and manufacturing storage provide a reliable guarantee for moisture and oxidation resistance.

The stainless steel nitrogen cabinet has a good anti-oxidation effect. The pressure in the nitrogen cabinet can be adjusted to generate a slight pressure difference between the inside and outside of the cabinet, avoid frequent opening and closing air intake caused by nitrogen loss, make the air pressure in the box uniform, and improve the oxidation resistance of items. Compared with the traditional nitrogen cabinet on the market, it can save about 30% of nitrogen under the same conditions.

In terms of nitrogen control, the flow meter plays an important role. It can be adjusted according to the flow rate. The inlet pressure is controlled within 0.2-0.4Mpa, and the flow rate is adjustable from 0 to 25 liters per minute. The larger the amount, the higher the nitrogen flow rate, which can reduce the humidity in the cabinet faster. And the nitrogen control system adopts an automatic program-controlled induction system, which is automatically controlled according to the set humidity. When the humidity in the nitrogen cabinet reaches the set value, the system will automatically cut off the nitrogen supply. When the set value is exceeded, the system will intelligently open the nitrogen supply.