Stainless Steel Cleaning Workshop Corrosion Resistant Industrial Oven

Product description

FeaturesPRODUCT FEATURES

Industrial ovens are essential for general heating procedures. From sample drying to chip glue curing, an accurate oven is one of the basic instruments that every laboratory or production shop should have. Yihexing stainless steel industrial ovens are suitable for a variety of heat treatment applications , temperature up to 200 degrees Celsius, ideal for drying, aging, glue hardening, preheating, curing and component testing, etc. With other upgrades, these industrial ovens can also be used for paint drying, plastic curing, sterilization, and cleaning or rubber, Silicone and epoxy curing applications.

Features

The box is welded and formed from a heavy-duty stainless steel frame

Configurable trolley

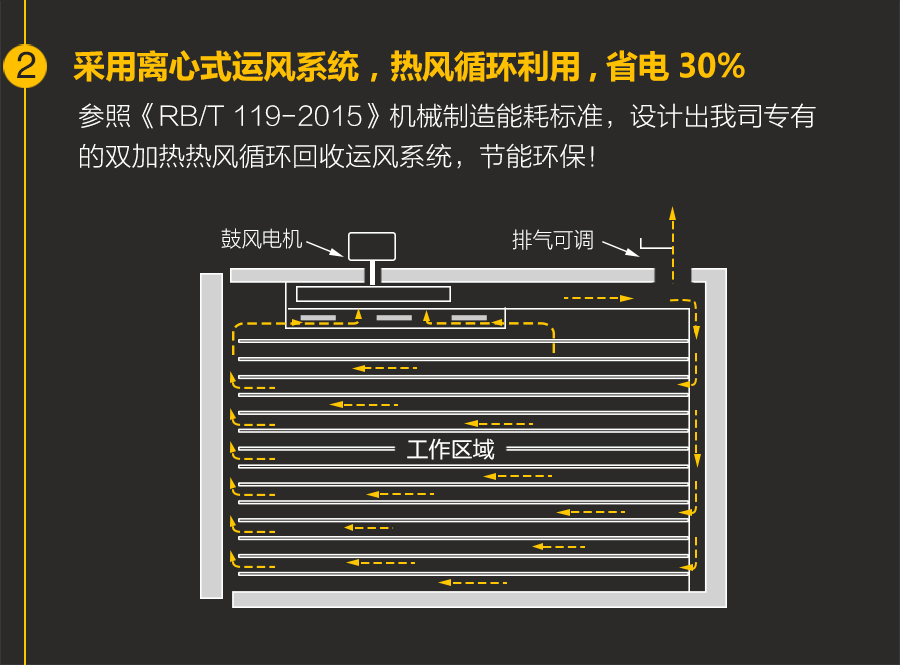

Adjustable air exchange system that allows fresh air to flow into the oven and exhaust air to leave the oven

Aluminum silicate insulation ensures that the surface temperature of the cabinet is safe and not hot

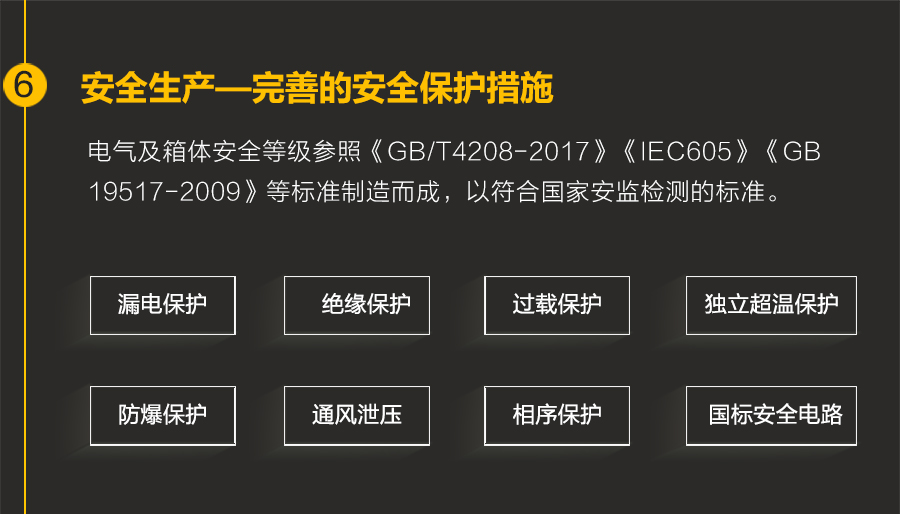

Independent over temperature protection

compact design

Large capacity horizontal air recirculation system and electric heating system for temperature uniformity of performance

excellent reliability

Options

touch screen control panel

Additional Thermocouple Measurements

Temperature recorder (paper or paperless)

Programmable controller, Ethernet and USB communication

Data logging and trend analysis

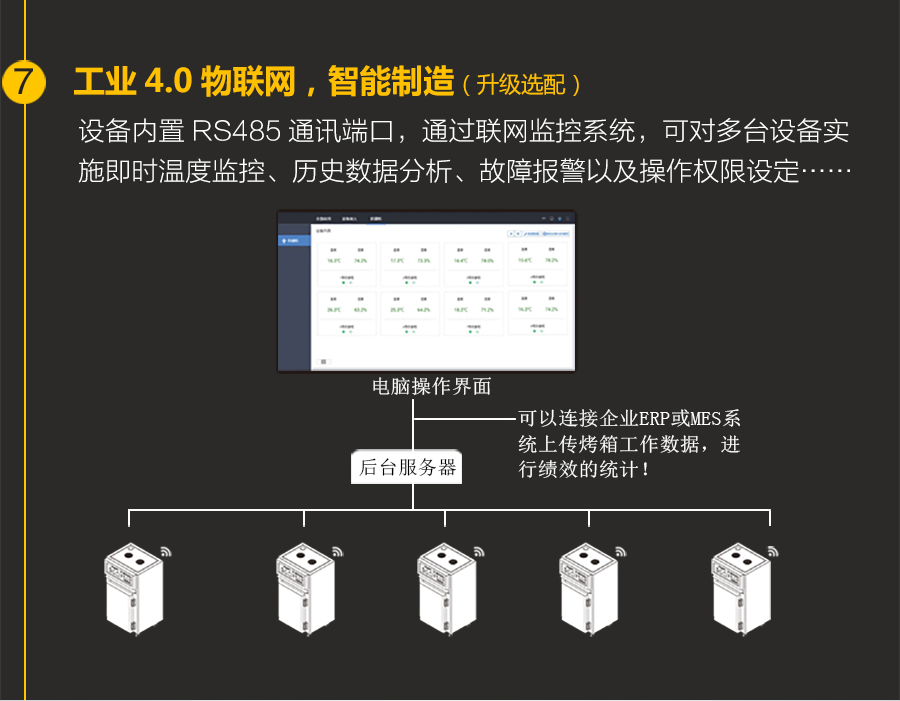

RS232\/RS485 communication converter

24 hour, 7 day digital process timer

Super heavy duty car rack

application

Ageing

test

curing

dry

Solvent, paint and paint drying

stress relief

industry

Aerospace

car

Military industry

electronic product

research and development

rubber and plastic

semiconductor

telecommunications

Optical Communication

Customized service

Shenzhen Jardine's custom industrial ovens are designed and manufactured to the exact specifications and heat treatment requirements of our customers. Check out examples of these products to see the wide range of industrial heat treatment systems we provide and manufacture for our customers. We are committed to providing high quality, full Aspect, efficient, low-maintenance oven systems that accept specific workspace sizes, materials, viewing windows, test holes or exterior colors.

We also provide thermal testing and analysis of your products to ensure a precise oven design for your specific application. If you have specific tolerances or specifications that must be met, please contact us with your requirements so we can ensure the equipment are designed, tested and tuned to meet these needs.

Product parameters

PRODUCT PARAMETERS

model | GM-DKX-B01 | GM-DKX-B02 | GM-DKX-B03 | GM-DKX-B04 |

Internal dimensions height x width x depth | 1550x1200x1000 | 1600x1200x950 | 1200x1300x800 | 1350x1260x1050 |

External dimensions height x width x depth | 1830x(1500 plus 235)x1140 | 2100x(1480 plus 235)x1100 | 1620x(1600 plus 235)x950 | 1880x(1560 plus 235)x1200 |

capacity | 1860L | 1820L | 1250L | 1780L |

heating power | 12kw | 12kw | 9kw | 12kw |

temperature range | Room temperature. Plus 20200 degrees Celsius | |||

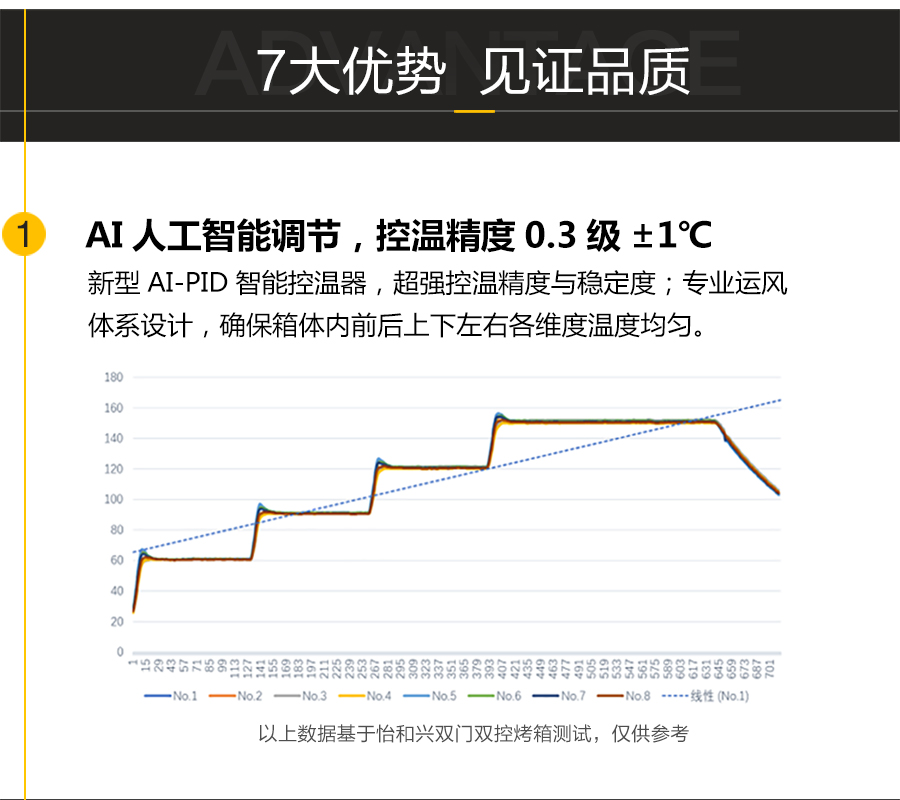

control precision | ± 1.0 degrees Celsius | |||

Temperature distribution accuracy | ±4 degrees Celsius (at 100 degrees Celsius), ±8 degrees Celsius (at 150 degrees Celsius) | |||

temperature rise time | About 30min (room temperature,→150 degrees Celsius) | |||

Operation function | Optional fixed temperature or programmed operation | |||

power supply | 3Mutually380V | |||

core configurationCORE CONFIGURATION

Send Inquiry